Stromectol

Ana Paola Uranga, MD, MBA

- Department of Emergency Medicine

- University of California, San Francisco-Fresno

- Fresno, California

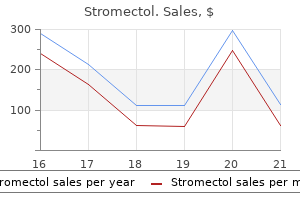

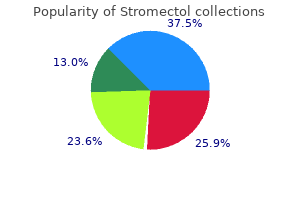

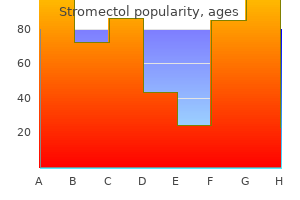

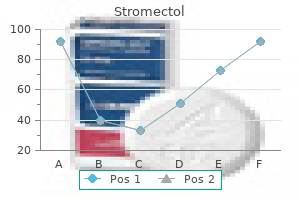

Stromectol dosages: 12 mg, 6 mg, 3 mg

Stromectol packs: 10 pills, 20 pills, 30 pills, 60 pills, 90 pills, 120 pills, 180 pills, 270 pills

Quality stromectol 12mg

Robots and automation may even reduce curiosity in finding decrease price manufacturing venues infection gums cheap stromectol 12mg without prescription. Not so way back bacteria jeopardy game order stromectol 12 mg overnight delivery, Japan was thought of a comparatively low priced site of manufacture infection in bloodstream cheap 12 mg stromectol free shipping, however that is definitely no longer the case. Thus, in some unspecified time within the future, delivery and brief provide strains could additionally be of extra interest than low prices of labor, low taxation, and lax environmental compliance requirements, all of which are prone to go away as a country develops. Robots may make attainable financial and low-cost manufacturing nearer to the target populations for a given group of patients. Robots will likely play a larger role as more customized healthcare merchandise are developed. These products shall be launched aseptically, and process validation within the manner we understand it now may not be absolutely attainable. Gene remedy and regenerative medicine products promise to be recreation changers within the therapeutic world, and they should be made close to the purpose of use. Manual assembly or filling as already lined is neither acceptable nor fascinating. Therefore, the logical resolution shall be robotics and very often robotics along side separative expertise of one sort or another. In this installation, the robots had been used for unloading stopper containers from the autoclave and charging the stopper bowl. Robots have also been used successfully in aseptic cell culture isolators and in radiopharmaceuticals applications. If we consider that the actual advantage of separative technology is the elimination of the direct human intervention, it becomes clear that the robot could be effective at mitigating contamination risk. Clearly, eliminating the human with automation can work just as successfully toward controlling contamination as separating the human from the aseptic surroundings. These resins are fed from large holding containers to hoppers on the machine; the plastic resin, generally within the type of beads, is melted and blown into molds under relatively excessive temperature and enough strain to type the container. Filling techniques, usually of the piston-pump selection, dose product into the container which is then warmth sealed. The containers, which can vary from single dose ampuls of 1 mL quantity or less to up to a liter or more, are successfully sterilized by the heat and pressure of molding. The filling systems are sterilized and generally cleaned in place; thus no aseptic connections are required. The ability of the compounding and filtration system to ship sterile product over an prolonged period of time is thus important. This requires careful design and engineering to ensure that prefiltration bioburden can be controlled through the duration of filling. Obviously, the upper the chance of the formulation to support microbial development and subsequently be vulnerable to the amplification of contaminants, the larger the inherent risk, so more care should be undertaken in design, engineering, installation, validation, and course of control. Antimicrobial agents could presumably be used in the cooling water system, however this raises a threat of chemical contamination ought to aerosolization occur. Fortunately, advancements in the design and due to this fact safety of cooling water techniques are evolving rapidly. In most circumstances, the bottles are subjected to a sterilization using a chemical or e-beam sterilization. Pre-filled syringes can be blow-molded in-line and sterilized in path to the filling process usually utilizing e-beam. In-situ or in-line blow molding of plastic bottles is a know-how that may proceed to evolve and which can be applied to even somewhat complicated dosing systems sooner or later. It appears logical that closures appropriate with hypodermic syringes might be developed and carried out. In-line or in-situ blow molding with or with out instantaneous warmth sealing is prone to be with us for many many years to come. In fact, hybridization of various manufacturing, environmental control, and automation/robots techniques in a single manufacturing operation appears more and more probably. The number of aseptic manufacturing methods sooner or later might be restricted only by the creativeness. The authors are satisfied that these methods will all have one important factor in frequent: each system will absolutely get rid of the direct human intervention. Future aseptic processing systems will fully eliminate human contamination risk and thus end in aseptically produced merchandise which are so protected that completely new regulatory approaches and efficiency expectations shall be required. Blind adherence to cleanroom derived ideas will gradual improvement and implementation and do both security and economic hurt to the end consumer. The processes utilized are dominated by thermal processes, with steam and dry warmth the most common. Chlorine dioxide, ozone, and nitrogen oxide have demonstrated a broad vary of antimicrobial exercise towards both Aseptic Filling Systems Dramatic adjustments in filling expertise, significantly for aseptically processed containers, are anticipated. The gear could be highly automated and designed to operate without human access and would come with the following working capabilities and options: � Provision for all routine interventions � Elimination of corrective interventions � Clean-in-place and/or sterilize-in-place capabilities for all product contact surfaces Future of Parenteral Manufacturing vegetative cells and spore forming microorganisms. Ozone decontamination of classified rooms was incorporated into the preliminary design of an aseptic processing facility for Novartis in Stein, Switzerland. Chlorine dioxide was one of many agents utilized for this treatment and demonstrated excellent efficacy with minimal problems. This expertise has led to extra applications on facilities coping with mildew and different types of microbial contamination. Chlorine dioxide has additionally been efficiently utilized for decontamination of isolator environments. For corporations looking for in-house gasoline sterilization capability, these agents might turn out to be extra frequent as information of their efficacy grows. They all provide an effective sterilization or decontamination alternative to current processes. Several completed dosage types have been launched using radiation sterilization, which beforehand would have proved impractical and prohibitively expensive. With the rising physique of data concerning radiation sterilization, makers of plastic containers, elastomeric closures, and different plastic materials have developed formulations and polymers which may be less susceptible to the damaging effect of radiation, increasing the possibilities for utility. Another factor influencing radiation usage is the rise in isolator installations, where electron beam systems are nicely suited for use for steady material infeed of heat-sensitive supplies. Several new radiation sterilization applied sciences are in active development, with a range of functions as various as full pallet e-beam and X-ray methods to small-scale techniques that might be inserted into individual containers. As with any new technology, once the preliminary resistance has been overcome, rising utilization follows. It seems clear that radiation sterilization will play an more and more prominent function in future production methods for parenteral dosage types, expanding upon the modest however very promising use now being skilled. Post-Aseptic Fill Sterilization Processes the preparation of sterile products has been dominated by two distinct approaches for a few years. Products are both manufactured utilizing aseptic processing or terminal sterilization. The distinction between the processes has at all times been quite sharp; the processes have been considered distinct and separate.

Order stromectol 12mg overnight delivery

Barrier coating of Teflon and proprietary polymer techniques on the formulation face of the closure have been very successful antimicrobial products buy stromectol 6mg lowest price. Particulate Matter 1015 the form and any causative occasions low grade antibiotics for acne cheap 12mg stromectol with mastercard, similar to nucleation seeds or surfaces and pH change antibiotics for dogs for sale discount stromectol 6mg without prescription. Certainly, any materials could provide a sufficient platform; however, small inert solids, such as glass or minerals, are perfect nucleators. Defect zones consisting of rough surfaces on the package walls also provide good sites for particle formation. One can think about silicone oil or immiscible liquids in the pharmaceutical fill to be potential nucleators, though their promotion of crystal growth is way much less likely than as formers or gatherers of material. Salt Formation Much more doubtless than solvates and polymorphs, newly shaped, less soluble salt forms are a danger in packages with potential for ion change, similar to (i) sealing with elastomeric septae, (ii) formulation components that may contribute ionic character, (iii) pharmaceutical water, (iv) insufficient cleaning of elements, and (v) ionic species from the glass container. Crystallization One of essentially the most dramatic events one may encounter in formulation stability is the generation of crystalline solids resulting in stability failure. The most critical elements are relative insolubility within the product solution, pH, ion content, temperature, and dilution. Acid or basic impurities dissolve within the product through the titration course of, and those dissolved impurities might still exist in resolution in a supersaturated state, not eliminated by filtration. The gelling course of is usually preceded by haze formation, with detection aided by Tyndall beam light. Impurities the presence of hint to low focus impurities is widespread and extra pronounced upon storage. Formulation bodily stability could also be compromised by the expansion of impurities-related particles, particularly for relatively insoluble moieties, within the presence of foreign material, immiscible liquids, and a growing inhabitants of different impurities, soluble or insoluble. This is characteristic of detergent molecules, therefore their desired functionality to "bridge" grease in water, and of many pharmaceutical compounds as nicely. The hydrophilic and hydrophobic ends of the molecule align in resolution, forming micelles or associations of molecular polarity with non-polar cores within the aqueous formulation. Certainly, extra complex variations of the micelle in nonaqueous systems and at the aspect of selected hydrophobic materials permit micelles to "carry" the comparatively water-insoluble substances in an aqueous medium. The associated teams are small in number (up to one hundred molecules is typical) and in dimension, ranging as a lot as 10 nm. The micellar group can solubilize other hydrophobic substances as a function of surfactant focus. There is a critical focus above which the surfactant varieties the micelle and the monomeric surfactant concentration stays fixed. Micellar formulation stability relies upon upon the soundness of the small micellar groups. Imagine the impact upon the molecular group the place one other hydrophobic material has been entrained in the hydrophobic core or is competing with the parent molecule. This competition is most significant in the instances of extracted natural moieties, such as plasticizers, for drug analogs, impurities, and degradation merchandise which are more hydrophobic than the mother or father and alter the solubilizing activity of the mother or father micellar groups. The importance of the micellar exercise in particle formation, or more realistically, particle appearance, is that seemingly secure, clear formulations can abruptly appear cloudy with the onset of nucleation or aggregation of material previously Nucleation Insoluble impurities may be current in a extra soluble type (amorphous) and precipitate in last product in a extra stable kind (crystalline). Hydrate or Solvate Formation these forms are more thermodynamically steady than the mother or father molecule and infrequently much less soluble than the anhydrous kind and thus represent vital menace to formulation stability in high concentration formulations experiencing dehydration and quantity loss. Accordingly, solvate crystal forms may also occur, although rarely in aqueous formulation. Polymorphism If conditions permit, especially in excessive concentration formulations, alternate bodily buildings may nucleate and reside in solid type. Chemically equivalent however bodily different, the conversion to the secure polymorph within the formulation is irreversible since return to the original polymorph is energetically unlikely. Again, the key for remediation of any crystallization event is full understanding of the solubility and stability parameters for 1016 held in resolution but now falling out of the micellar groups because of competitors with extra amenable substances. Parenteral Medications But where does the boundary between seen and subvisible particle dimension (and type) exist Fundamental to the development of sturdy formulae in stable packages is utilization of many methods of overlapping detection to be able to reveal all variations of contamination. In this design, any appearance change or particle content increase as a result of a number of of these elements allows their detection, isolation, identification, and knowledge to enhance the formulation-package design. Oligomers Monomers or single molecules will be a part of by way of chemical processes to kind dimers, trimers, and oligomers (a restricted assemblage of monomers, wanting polymerization). The importance of the larger molecules to the solution integrity is their inherent solubility, especially in regard to micellar energetic ingredient formulations and with specific emphasis for subsequent dilution of the formulation. It is directly related to solubility, and thus most prevalent in excessive focus and saturated formulations, and people requiring micellar affiliation for stability (solubility). Leaching/Extraction Extractables: "Substances that may be extracted from plastic materials/systems using extraction solvents and/ or extraction conditions which are expected to be more aggressive than the circumstances of contact between the material/system and a finished drug product. At every level of contact for parts of the formulation, potential for including extracted substances have to be investigated (56). A case history describing the bloom of an extracted substance in a concentrated active formulation occurred as a result of the extraction of a phthalate ester from a course of filter-housing into the lively moiety mother liquor during synthetic course of, yielding a significant visible cloud within the in any other case acceptable ampoule injectable product (26). Instrumentation, calibration schemes, and vendor assist make this methodology a far more routine and regimented software. Membrane methodology is time-consuming because of its labor-intensive nature and has a quantity of operational parameters that should be controlled or will add to counting and sizing error, Table 46. Both tests are valuable, and practitioner labs will need to have proficiency in each technique. Strong formulation improvement and new product testing laboratories will maintain each strategies. Analytical approaches and sensitivity and manufacturing controls and tools proceed to be refined, and the improved physical and chemical quality in trendy pharmaceutical merchandise has been outstanding. Simple product look methods and more sensitive visible inspection strategies must be appreciated for their capability to detect low ranges of heterogeneous, insoluble, non-volatile substances not detected by instrumental means. Beginning in early Development, the use of visible inspection and human analysis of product stability units and a selection of illumination configurations should not be underestimated. More quantitative strategies similar to nephelometry, turbidimetry, and shade determinations provide early detection of bodily change and instability in product forms. The perfect is to establish every particle or a minimum of categorize in pursuit of the supply. Clues to the identification and adjustments related to the incident may reside with the initiator or owner of the process, assay, or system that discovered the particles. Representative reject containers are evaluated to affirm particulates in the rejected units. Typical categories of particles, by visual look or microscopical look, and the character of those isolates, are explored to determine elementary properties and clues to their presence. In this first sequence, visual examination and low magnification stereomicroscopical analysis aids categorization of the particles by dimension, physical options, solubility, hardness, and response to chemical reagent teams. Obvious particulate species common to the microscopist and sometimes unknown by standard laboratory assay could also be identified by this stage, such as cellulosic materials and all types of organic solids, together with fibers, hairs, and insect-related matter, generally extrinsic materials.

Buy stromectol 6 mg with visa

Separate consideration of interventions as both inherent or corrective is important as a result of the design approaches bacteria 5 second rule cartoon 12 mg stromectol with mastercard, execution particulars antibiotics not safe during pregnancy stromectol 6 mg free shipping, threat mitigation means antibiotics for acne scars discount stromectol 6mg on-line, and operational views remain different. Inherent interventions require willpower of a most well-liked methodology and training of personnel of their execution. Corrective interventions have a higher reliance on operator experience and on aseptic method as a end result of they differ in execution. The objective should be to remove all corrective interventions, particularly the crucial correctives. In many aseptic operations, it is a difficult but extraordinarily valuable danger mitigation exercise. The designation of interventions as both inherent or corrective, whereas helpful in understanding their design and execution, is less helpful in threat evaluation. It seems logical to think about length of the intervention (seconds within the crucial zone) as a superior various to intervention type in the estimation of risk. A prolonged inherent intervention would thus be thought-about more risky than a simple corrective one. Time serves as a more definitive and fewer subjective means to assess the potential influence of an intervention in comparison with the sort of intervention. The goal in all aseptic processes is to continuously reduce the frequency of interventions no matter their sort: inherent, corrective, or critical corrective. For instance, the frequency of in process weight checks ought to be primarily based upon the efficiency of the filling equipment and never an arbitrary time interval. Better nonetheless, if potential, the implementation of, or addition of, automated weight checking will quantitatively cut back danger additional by eliminating the intervention completely. Nothing can reduce the frequency of a crucial danger as impactfully as its elimination. The solely actually "perfect" intervention is one that has been eradicated from the aseptic course of. The distance between where the intervention is performed and the closest uncovered sterile or sterilized material instantly affects danger. Logically, the shorter the space between sterile objects and the contamination producing personnel performing the intervention, the greater the potential is for contamination to be transferred throughout that distance. A easy 835 relative distance scale was used within the initial A&A method for the sake of simplicity. William Whyte, an early proponent of formal aseptic risk assessment, instructed the use of the inversesquare rule for estimating the dispersion of microorganisms from a supply. This rule depends upon two assumptions: the existence of a degree supply of microorganisms that disseminates them very similar to a light bulb casts mild and that microorganisms disseminated from that supply would uniformly populate the encircling setting. However, different components, including electrostatic costs, can alter the direction by which airborne contaminants move. The use of the inverse-square rule, although it is in all probability not precisely quantifiable, places higher weight than the unique A&A technique on interventional activities carried out closer to uncovered sterile materials. Although imperfect, the inverse-square rule is a extra goal means for contemplating the effect of distance in risk estimation. Ultimately, the A�A methodology permits for a mathematically easy technique of evaluating risk. It is typically recommended that values be rounded to the next complete integers or to the closest ten or hundred place. In this example, one can see that roughly 75% of the chance accrued from the one most intensive and invasive intervention. For basic design and know-how choice functions, the simplified A�A method can be utilized, and as famous beforehand, in follow, it has been discovered to correlate properly to the precise observed risk when older facilities and their performance are correlated to newer ones or those using advanced technology. It should be cautioned that microbiological contamination data were employed in the Katayama et al. Frequency is the variety of interventions of a given kind that happens over an outlined time. Risk assessment must be adopted by a far more important activity-risk mitigation. However, recognizing the change in weather conditions makes the driving force safer solely when he or she adjusts their driving to swimsuit the circumstances. Unless the driving force adjusts his/her speed, turns on the windwipers and the lights, there has been no reduction in danger. Once the basic facility and know-how choices have been made, there are options inside these alternatives that should be thought-about as well to further refine the technology to be carried out. The design course of for an aseptic facility is a lengthy course of: continuing from conceptualization, preliminary and detailed design with a myriad of selections, and decisions to be made all through. Considering the core goal, the next preferences may be defined: � Design for ease of execution via the selection of construction supplies, designing for ease of access, and detail elements that facilitate both cleansing and decontamination of the core surroundings. The use of unidirectional air is extra crucial for manned operations, than for fully separative applied sciences. It would be far preferable to define and utilize design ideas that result in the most effective aseptic processing design for a specific utility. Facilities the selection of an acceptable aseptic know-how is central to almost all the subsequent design selections. The selection is usually Risk Assessment and Mitigation � Materials and personnel airlocks must be utilized to prevent inadvertent pressure reversal. This may find yourself in fewer interventions in both the critical and background environments. Primary Packaging (Containers/Closures) the containers and closures essential are perhaps an important objects in an aseptic course of. The ease of their introduction, transfer, motion, placement, and closure should all be efficiently achieved by the gear with a minimal of human intervention. It must be evident that they want to persistently process throughout the system, and thus, larger high quality parts may be a required that what might be customary in a less-advanced (and thus markedly much less capable) aseptic processing system. Higher Acceptance Quality Limits for defects can lead to a discount in the want for interventions. Inventories of materials within the aseptic environment (especially the important environment) must be minimized. Equipment/Utensils In aseptic processing, the processing equipment situated inside the critical environment is essential to success with aseptic processes. The reliability of the gear and the sophistication of its design are paramount in minimizing the necessity for interventions. Their set up following sterilization often entails substantial and prolonged interventions that may compromise any seeming advantage provided by the sterilization). Wherever potential, they should be self-clearing to get rid of the need for personnel intervention in the occasion of a misfeed, jam, or other fault. Product Delivery of sterile product to the important zone is easily accomplished with minimal danger utilizing either immediately piped connections or real-time transport protocol connection systems. Sterilizing filters throughout the enclosure should be utilized on every service simply previous to the use point. Parenteral Medications � Interventions carried out during aseptic processing no matter their simplicity have to be acknowledged as increasing the risk of contamination dissemination.

Generic stromectol 12 mg

Swab Sampling Technique bacteria que causa cancer de estomago buy generic stromectol 6 mg online, Reliability antibiotics for uti and exercise generic stromectol 12mg line, and Training Swab sampling must be reliable for cleaning validation to be legitimate 5 infection control measures effective 6mg stromectol. Swab sampling is reliable when technicians who do sampling are educated and reveal competency. Some organizations contemplate swab sampling to be a mundane activity that might be carried out without any coaching. Perhaps their rationale is that since everyone has used a Q-Tip throughout their lives, they have to be certified to perform swab sampling. For analytical outcomes of the swab samples to be dependable, the cleansing personnel should have the power to get well residues from tools surfaces quantitatively and consistently. It is due to this fact essential that personnel who carry out swab sampling for cleaning validation be formally trained. The training process should simulate acceptable worst-case conditions related to the product residues which would possibly be sampled at the web site. The coaching should embrace acceptable quantitative acceptance criteria to show the competence of the trainee. Periodic recertification of personnel is recommended to reinforce and maintain the manual dexterity and skills required for swab sampling. If an auxiliary implement similar to an extension pole is utilized in sampling, the coaching Cleaning Validation Lifecycle Stage 2-Process Qualification Application of Process Validation Stage 2 Process Qualification concepts to cleaning validation includes work carried out to reveal and make sure a profitable cleaning process. Validation performance consists of the activities and documentation to reveal the successful growth of a new process or the successful implementation of change to a validated process. These activities are primarily based on the Stage 1 course of understanding work described previously. After cleansing, tools is inspected and tested to show that acceptable stage of soil has been attained. The work of Stage 2 ought to be commensurate with the identified or expected danger related to cleaning. Many organizations erroneously consider validation performance to be the whole concept of validation. The efficiency of multiple full-scale conformance lots confirms the acceptability of manufacturing processes as beforehand designed and developed. All cleansing equipment should be qualified when used in Stage 2 process qualification. All analytical strategies, including instrumentation, must be qualified when utilized in Stage 2 course of qualification. A plan for maintaining the cleaning validated state, Stage 3 of cleansing course of validation, should be mentioned in the last validation report. Parenteral Medications that validation tests will meet their predetermined acceptance standards. The accredited cleaning validation protocol must be executed with an expectation of complete success. Techniques, sampling, testing, and related activities ought to have been tried earlier than being used in validation. Validation efficiency must verify the acceptability of the cleaning course of as beforehand developed. Completion of Stage 1 Technical Development Work All work supportive of the ultimate cleaning process should be accomplished prior to initiation of Stage 2 Process Qualification. Completion of the aforementioned activities includes accomplished documentation describing all of the above. The work described in these initiatives must instantly help performance of the cleansing course of, tools and utilities used within the course of, and sampling and testing required to validate the process. The aforementioned documentation should be referenced in cleansing validation documentation and be readily available for audit as needed. Considerations Prior to Cleaning Process Performance Initiation of Stage 2 Process Qualification is a critical milestone within the cleansing validation. Initiation of Stage 2 Process Qualification implies that the cleansing course of has been absolutely developed. Stage 2 cleaning course of efficiency should verify the cleansing course of improvement work. There have to be good confidence Master Cleaning Procedure Record the last word results of Stage 1 cleansing course of improvement is the Master Cleaning Procedure Record. This document is equal to the master manufacturing batch document containing all manufacturing process steps for a pharmaceutical product. A copy of the Master Cleaning Procedure Record is issued every time the cleansing course of is utilized. The specific procedural steps and course of parameters within the Master Cleaning Procedure Record must be addressed and justified within the cleaning course of growth report. The Master Cleaning Procedure Record must embrace detailed process steps in the manner of a Cleaning Validation-Lifecycle Approach manufacturing batch report. Details should embody quantitative preparation of cleaning agent liquids, gear disassembly, quantitative process steps, and other related steps in the cleaning process. Performance of all related steps should be signed and dated by personnel performing these steps demonstrating accountability for precise efficiency of the required process. The Master Cleaning Procedure Record should affirm that cleansing is a specified procedure that have to be rigorously carried out and never an exercise during which personnel "do whatever it takes to get the job done. Sampling, testing, and acceptance standards justification and rationale are discussed in these documents. The validation initiation/plan and validation protocol are accredited by the site validation approval committee. This exercise represents the fruits of all course of understanding work, together with R&D, scale-up, technology transfer, and commercial-scale improvement. These paperwork must be a logical extension and according to Stage 1 improvement paperwork demonstrating the scientific and technical foundation for the cleaning process. This exercise represents the end result of all course of understanding work, together with R&D, scale-up, technology switch, and commercial-scale improvement of the cleaning course of. It contains precise execution of the cleansing process to be validated, sampling, and associated testing. The following are discussed: � Preparation for cleansing validation � Conformance lot cleaning-Execution of the cleansing process document � Conformance lots sampling and testing. Cleaning Procedure Records for Conformance Lots the cleaning procedure records for conformance lots are copied from the Master Cleaning Procedure Record. A copy of the Cleaning Procedure Record must be included in the cleaning validation plan or protocol to specifically determine the method being validated. Preparation for Cleaning Validation Preparation for cleansing course of validation contains activities related to cleaning course of efficiency.

Purchase 6mg stromectol fast delivery

Other considerations might include prior data virus list cheap stromectol 3 mg otc, manufacturing historical past infection red line on skin purchase stromectol 3 mg amex, gear failure antibiotics for uti intravenous generic stromectol 12mg without prescription, and human error. The scoring range was in keeping with scores assigned for Severity and Occurrence with the best scores assigned to process parameters with limited or no means of Detection. Considerations embrace gear control capabilities, deviation alarms, and monitoring. A final Risk Priority Number is assigned based mostly on multiplying the scores for Severity, Occurrence, and Detection (S � O � D) with appropriate rationales for each course of parameter described. The analysis of functional relationships can distinguish the extent of threat and serves to prioritize relevant studies or experiments required to consider the chance. Another approach to identify and analyze risks and arrange them in an orderly trend is to use an Ishikawa Diagram. Frequently, Ishikawa diagrams are used to establish the potential causes of a selected drawback. For example, the risk of having manufacturing defects in a tablet could be traced to the potential sources of variability that create that danger. Each of those instruments alone or together with each other can present a preliminary and systematic evaluation of threat. Subsequent assessments may distinguish acceptable dangers from dangers that require controls and/or strategies for measuring management. Parenteral Medications � Use of formal threat assessment criteria to identify and differentiate crucial from noncritical sources of variability and decide which variables are necessary to study and control. As the lifecycle of a product evolves from pharmaceutical development via know-how transfer, during business manufacture and with the introduction of product enhancements and alternative formulations, the functional relationships between parameters and attributes and high quality attributes of the product could change. Reassessment of useful relationships, adjusting design house boundaries to accommodate modifications within the manufacturing course of, and establishing new design house increase process understanding and product information and supply improved high quality assurance of the product. Risk Evaluation Identifying the sources of variability among course of parameters which will pose risk to high quality attributes permits for an analysis of the impact and probability of that threat causing harm. The importance or magnitude a risk poses typically results in the development of an experimental strategy to consider the extent of threat. The practical relationships between process parameters and high quality attributes within the focus areas of a manufacturing process present the chance to consider the risk quantitatively and characterize boundaries of that risk by way of experimentation. Design of Experiments DoE is a structured and statistical method to evaluating the interactions of process parameters and their influence on quality attributes [31�36]. Multiple parameters are studied concurrently, which allows the estimation of interactions between components. The use of DoE provides efficiency for estimating parameter results and control over precision of response prediction in the case of response surface designs. They are complete in nature, eliminate subjective assessments, and supply information with a wide inductive foundation. Model building can be utilized to condense the uncooked data into methods of equations, which describe relationships and thereby facilitate interpretation. Sequential experimentation offers incremental understanding of the relationship between parameters and high quality attributes by converging to conditions which produce the desired product. Estimation of all effects including interactions offers a wider inductive foundation for the experiment. The statistical approach to DoE is beneficial in quantitatively characterizing the level of danger that any given parameter or attribute might pose in a multivariate expression. The variety of statistical approaches generate information that can be used to optimize the understanding of the boundaries of parameters and attributes in a design area and thereby enhance the understanding their relative danger might have on quality of the product. Scientific and risk-based assessments meet several basic goals of QbD: � Risk assessments are useful for characterizing and rating attributes process parameters semiquantitatively relative to their influence on safety and efficacy. Risk Control Decisions on what degree of risk is suitable have incessantly centered on which parameters and attributes are "important. For instance, genotoxic impurities could be purged and managed within the third step of a six-step synthesis of a drug substance. Stoichiometry, temperature, and pH of the reaction have been demonstrated to impact control of genotoxic impurities. Subsequent demonstration that the process persistently operates inside the design area reduces the danger. In many instances, an appropriate threat administration strategy will reduce the danger to an appropriate stage the place severity and likelihood could additionally be mitigated by adherence to parameter and attribute boundaries. The acceptability of risk is commonly a choice that balances the presumed impression of the danger relative to applicable controls to mitigate that impression. However, if the drug itself is mutagenic and is indicated for firstline therapy for breast most cancers, the presence of these impurities should be balanced with the good thing about the drug and its length of use. If reduction or elimination of genotoxic impurities is value prohibitive or results in different quality issues, then acceptance of limits for these impurities that exceed the standard regulatory expectation could additionally be justified. The incapability to affiliate quality attributes with security and efficacy will increase the extent of uncertainty in assessing danger. Furthermore, the inherent difficulty to precisely characterize many biological molecules reduces the opportunities to develop concrete course of understanding. However, examples and case research describing the application of QbD rules and, particularly, quality risk administration approaches have demonstrated restricted success [38�42]. QbD rules could be utilized for large-molecule drug product growth (formulation and process) may be carried out and are illustrated in sections under. Design Space for Drug Product Drug product development typically includes an assessment of the formulation (via a DoE study) and the manufacturing process. In this part, an example of a formulation DoE is supplied, which defines the factors that impression the quality attributes. This will be adopted with an assessment of 1 unit operation lyophilization where the important parameters that impact high quality attributes are defined. Based on the evaluation of prior information, impact of formulation excipients on the standard attributes throughout storage needs to be assessed. A formulation DoE design was ready for a protein at a focus of one hundred fifty mg/mL. The examine was performed with 1 mL fill volume in a prefilled syringe with a coated plunger for closure. A full-factorial experimental design was utilized, for finding out every issue individually and the interactions between the factors. A total of 15 different formulations together with the formulations with varying excipient levels, and twin heart point formulation had been evaluated in the course of the stability research. The stability research was carried out at 5�C (intended storage condition), 25�C (stress condition), and 40�C (accelerated stress condition), and quality attributes such as total impurities, protein concentration, pH, and subvisible particles (10 �m and 25 �m) per container were assessed. The knowledge at 25�C for 6 months were obtained, and the ensuing analyses are offered in this section. A important change in % complete impurities was seen in samples on the high and low pH conditions throughout storage for as much as 6 months. Risks ought to be characterised by their respective and related relationship to quality attributes and process parameters and documented in a logical method that exhibits the relationships between product high quality and the attributes and parameters that influence high quality. A common abstract of the risk assessment strategy and justifications for decisions regarding the attributes and parameters that warrant concern is useful to regulatory authorities and must be clear and reproducible.

Squalamine. Stromectol.

- Dosing considerations for Squalamine.

- Are there safety concerns?

- How does Squalamine work?

- Infections, cancer, and eye conditions in people with diabetes.

- What is Squalamine?

Source: http://www.rxlist.com/script/main/art.asp?articlekey=96733

Order 6mg stromectol with amex

In early levels of the illness antimicrobial innovation alliance stromectol 6 mg otc, neurodegeneration of areas liable for cholinergic transmission results in a cholinergic deficit treating dogs for dry skin purchase stromectol 3mg with mastercard. As the illness progresses virus x 1948 purchase 3mg stromectol free shipping, widespread neurodegeneration causes imbalance in all neurotransmitter systems. These are primarily situated in mind regions concerned in studying, reminiscence, and emotional behaviors such because the hippocampus inside the medial temporal lobe of the cerebral cortex, basal forebrain, and amygdala. Although standards are nonetheless being evaluated to understand the levels of cerebrovascular pathologies that contribute to cognitive impairment, epidemiological studies have discovered that the presence of vascular and metabolic threat elements throughout midlife are most strongly related to risk of cognitive impairment and dementia. The neurons that provide a lot of the cholinergic innervation to the cortex are prominently affected. Currently, there are biological Plaques the A protein is current in neuritic plaques in a unhazardous, soluble kind in human brains. Inflammation occurs secondary to clusters of astrocytes and microglia surrounding these plaques. Blocking acetylcholinesterase, the enzyme that degrades Ach in the synaptic cleft, results in an increased degree of Ach with a aim of stabilizing neurotransmission. It impacts cognition through facilitation of connections with cholinergic neurons within the cerebral cortex and basal forebrain. Evidence of serious cognitive decline from a earlier stage of performance in one or more cognitive domains (complex consideration, executive function, studying and reminiscence, language, perceptual-motor, or social cognition) primarily based on: 1. Concern of the individual, a educated informant, or the clinician that there was a major decline in cognitive operate and a pair of. A substantial impairment in cognitive efficiency, ideally documented by standardized neuropsychological testing or, in its absence, another quantified clinical assessment B. Insidious onset and gradual development of impairment in a number of cognitive domains (for major neurocognitive dysfunction, a minimal of two domains have to be impaired) C. Criteria are met for either probable or potential Alzheimer disease as follows: For Major Neurocognitive Disorder: Probable Alzheimer illness is recognized if both of the next is present; otherwise potential Alzheimer disease must be recognized. Evidence of a causative Alzheimer disease genetic mutation from family history or genetic testing 2. Clear evidence of decline in memory and studying and no much less than one other cognitive area b. Evidence of modest cognitive decline from a previous stage of performance in a quantity of cognitive domains (complex consideration, govt function, studying and memory, language, perceptual-motor, or social cognition) based mostly on: 1. Concern of the individual, a educated informant, or the clinician that there was a mild decline in cognitive function and 2. A modest impairment in cognitive performance, ideally documented by standardized neuropsychological testing, or in its absence, another quantified clinical evaluation B. Impairment in motor, behavioral, and sensory functioning occurs later in the sickness. Assess all comorbid medical issues and drug therapies that may affect cognition three. Secondary objectives include treating psychiatric and behavioral signs which will happen during the course of the illness. Additionally, psychiatric and behavioral signs that happen through the course of the disease should be handled as they happen. Treatment options, authorized and monetary decisions, and course of the sickness should be mentioned with the patient and relations. The selection of one ChE over another ought to be primarily based on differences in mechanisms of action, antagonistic reactions, titration schedules, potential drug interactions, and patient and caregiver choice. Patients must be switched to one other ChE inhibitor from their initial ChE inhibitor if they show an initial lack of efficacy, initially respond however then lose scientific profit, or experience safety/ tolerability points. The switch should also be based mostly on realistic expectations of the patient and/or caregiver. The 23-mg dose confirmed a small improvement in cognitive symptoms compared to the 10 mg/day dose; however, there was no enchancment in total functioning, and there was a higher incidence of antagonistic results. Namzaric, a fixed-dose combination of extended-release memantine and donepezil (14/10 mg and 28/10 mg), was lately approved. If unwanted effects cause intolerance, a number of doses could be held, after which dosing may be restarted at the similar or next decrease dose. Galantamine may also enhance glutamate and serotonin levels, however whether or not this brings further benefit is unknown. Similar to donepezil, if inhibitors are given concurrently with galantamine, increased cholinergic unwanted facet effects ought to be monitored. Closer monitoring should be carried out if memantine is given concurrently with a ChE inhibitor. Mechanisms by which these compounds are thought to work include7: � Reducing ranges of brain A or manipulating its configuration � Targeting proteins Patient Encounter Part 2 the patient returns to the clinic in 6 months. Her memory symptoms have slowed of their decline, but lately she has been agitated at bedtime and speaking to her deceased sister. The son is especially involved concerning the symptoms and wants to know what he could do to help. What nonpharmacologic and pharmacologic interventions could presumably be beneficial for the agitation and psychosis Homotaurine is naturally occurring in seaweed and thought to interfere with amyloid plaque formation and subsequent degeneration of neuronal cells. A meta-analysis concluded that solely 17% to 18% of dementia patients demonstrated remedy response to atypical antipsychotics. Fifteen of 17 trials investigating olanzapine, aripiprazole, quetiapine, and risperidone in aged demented patients with behavioral problems confirmed a rise in mortality in contrast with the placebo-treated teams (1. Causes for these deaths were heart-related events (heart failure and sudden death) and infections (mostly pneumonia). Therefore, it is very important individually assess and stability the risk versus good factor about antipsychotic use in this inhabitants. Both the American Society of Consultant Pharmacists and the American Psychiatric Association have published statements relating to using antipsychotics to treat agitation and psychosis in dementia. A recent trial instructed a scarcity of good thing about sertraline and mirtazapine compared with placebo and an elevated danger of opposed results. Patient Encounter Part three the affected person returns to the clinic for follow-up 1 12 months later. Assess the Information: � Determine whether or not the affected person has any other illness state (ie, depression) or is taking any medicines that could contribute to cognitive changes in the elderly. Develop a Care Plan: � Select an acceptable ChE inhibitor to avoid drug�drug interactions and adverse effects and in consideration of value and affected person choice (see Tables 29�6 and 29�7). Implement the Care Plan: � If wanted, present sufferers and caregivers details about way of life modification, and refer them to assist when needed. Follow-up: Monitor and Evaluate: � Follow up at wanted intervals to assess effectiveness and safety of therapy. Review medical history and bodily examination findings, lab exams, and outcomes of different diagnostic exams. Alzheimer Disease within the United States (2010�2050) estimated utilizing the 2010 census.

Syndromes

- Sexually transmitted infections such as gonorrhea or chlamydia

- Your hair loss begins after starting a medication.

- Too much blood circulation in the lungs may cause extra fluid to build up in and around them, making it difficult to breathe.

- Bleeding scan (nuclear medicine)

- Excessive bleeding

- Shortness of breath

- PET scan of the heart

- What medicines do you take?

- Hops on one foot without losing balance

Generic 6mg stromectol with mastercard

Avoid use if hypersensitivity to soy or egg products bacteria 8000 order stromectol 6 mg with amex, pathological hyperlipidemia treatment for dogs dermatitis order stromectol 12 mg visa, lipoid nephrosis antibiotics for staph acne buy stromectol 3 mg with mastercard, or acute pancreatitis. Preferred agent for many hypertensive emergencies, pregnancy, except acute pulmonary edema. For infusion rates over or equal to 4�10 mcg/kg/min or duration more than half-hour, coadminister thiosulfate to prevent cyanide toxicity. Reports of intrauterine growth restriction with atenolol within the first and second trimesters B: acebutolol, pindolol, sotalol C: esmolol, metoprolol, nadolol, nebivolol, penbutolol, propranolol, timolol D: atenolol Limited data; no association between drug and congenital defects when the mom took the drug early within the first trimester, but variety of exposures is small Limited knowledge; nifedipine within the first trimester was not related to increased charges of major birth defects, however animal data were associated with fetal hypoxemia and acidosis. Patient Care Process Collect Information: � Perform a drugs history including prescription and nonprescription drugs, herbal merchandise, and dietary dietary supplements as nicely as historical past of allergies to medications or different substances. Develop a Care Plan: � Collaborate with affected person to establish possible way of life modifications (Table 5�6). Implement the Care Plan: � Educate and provide resources about implementing life-style modifications and changes in drug therapy including treatment administration, storage, adherence, and potential opposed effects and their administration. Individualizing hypertension therapy with impedance cardiography: a meta-analysis of published trials. The plasma renin take a look at reveals the contribution of physique sodium-volume content material (V) and reninangiotensin (R) vasoconstriction to long-term blood pressure. European Society of Hypertension position paper on ambulatory blood stress monitoring. Salt sensitivity, a determinant of blood pressure, cardiovascular disease and survival. Recommendations for blood strain measurement in people and experimental animals. The Essentials of High Blood Pressure: Basic Science, Population Science, and Clinical Management, 4th ed. Comparative antihypertensive effects of hydrochlorothiazide and chlorthalidone on ambulatory and workplace blood pressure. Treatment of hypertension in patients with coronary artery illness: a scientific assertion from the American Heart Association, American College of Cardiology, and American Society of Hypertension. A comparison of outcomes with angiotensin-converting�enzyme inhibitors and diuretics for hypertension in the elderly. The lupus syndrome induced by hydralazine: a common complication with low dose remedy. American College of Obstetricians and Gynecologists; Task Force on Hypertension in Pregnancy. Ventricular dysfunction can even contain either the left or right chamber of the center or each. This has implications for symptomatology because predominant right-sided failure manifests as systemic congestion, whereas predominant left-sided failure results in pulmonary signs. Expulsion of blood occurs throughout systole, or contraction of the ventricles; diastole pertains to filling of the ventricles. Average hospital size of stay is estimated to be between 4 and 6 days, a quantity that has remained fixed over the previous decade. Sudden cardiac death is the most common reason for demise, occurring in roughly 40% of sufferers. An enhance in venous return to the left ventricle ends in the stretch of cardiomyocyte sarcomeres (or contractile units) and a subsequent enhance within the variety of cross-bridges shaped between actin and myosin myofilaments. This results in an increase in the drive of contraction primarily based on the FrankStarling mechanism. Contractility, also recognized as the inotropic state of the guts, is an intrinsic property of cardiac muscle incorporating fiber shortening and tension improvement. Contractility is influenced to a big degree by adrenergic nerve exercise and circulating catecholamines similar to epinephrine and norepinephrine. They embrace the Frank-Starling mechanism, tachycardia and elevated afterload, and cardiac hypertrophy and reworking (Table 6�2). Aldosterone in flip stimulates sodium and water retention in an try and improve intravascular quantity and hence preload. However, in a failing heart, alterations in the contractile filaments cut back the flexibility of cardiomyocytes to adapt to will increase in preload. Sympathetic activation additionally enhances contractility by increasing cytosolic calcium concentrations. In addition to myocyte dimension and extracellular matrix changes, coronary heart geometry shifts from an elliptical to a less efficient spherical shape. Ventricular hypertrophy, an adaptive enhance in ventricular muscle mass due to the expansion of present myocytes, happens in response to an elevated hemodynamic burden similar to quantity or stress overload. Eccentric hypertrophy involves a rise in myocyte dimension in a segmental trend, as opposed to the worldwide hypertrophy occurring in concentric hypertrophy. Although hypertrophy helps to cut back cardiac wall stress in the brief term, continued hypertrophy accelerates myocyte cell dying by way of an overall enhance in myocardial oxygen demand. Relationship between cardiac output (shown as cardiac index) and preload (shown as pulmonary capillary wedge pressure). Several mechanisms relate to diminished responsiveness to catecholamines (eg, norepinephrine) as cardiac function declines. Arginine Vasopressin Vasopressin exerts its results through vasopressin sort 1a (V1a) and vasopressin kind 2 (V2) receptors. Vasopressin increases preload, afterload, and myocardial oxygen demand within the failing heart. This adaptive mechanism has deleterious penalties as a result of extreme sodium and water retention worsen the already elevated ventricular filling pressures. In addition, evidence supports the position of aldosterone as an etiological issue for myocardial fibrosis and cardiac reworking by inflicting elevated extracellular matrix collagen deposition and cardiac fibrosis. In addition, the mixture of those a number of results is likely answerable for the elevated threat of sudden cardiac dying attributed to aldosterone. Natriuretic peptides decrease sodium reabsorption in the accumulating duct of the kidney. However, the increase in preload and afterload in the setting of a failing ventricle leads to elevated filling pressures and additional impairment of cardiac operate, which manifests as systemic and/or pulmonary congestion. It is helpful to keep in mind that congestion develops behind the failing ventricle, brought on by the lack of that ventricle to eject the blood that it receives from the atria and venous return. L O three General Signs and Symptoms Refer to the Clinical Presentation and Diagnosis of Chronic Heart Failure textbox for added descriptions of indicators and symptoms. It normally happens in dependent areas of the body, such as the ankles (pedal edema) for ambulatory patients or the sacral region for bedridden patients. Patients could complain of swelling of their feet and ankles, which might lengthen up to their calves or thighs. Abdominal congestion could trigger a bloated feeling, stomach ache, early satiety, nausea, anorexia, and constipation. Abdominal edema can lead to delayed absorption of oral medications, including diuretics used to treat congestion. Often sufferers could have issue fitting into their sneakers or pants because of edema. This is performed by inspecting the right internal jugular vein for distention or elevation of the pulsation whereas reclining at a 45-degree angle.

Stromectol 12mg with amex

Particle measurement antibiotic resistance map buy stromectol 6mg without a prescription, respiration sample antibiotic xan purchase 6 mg stromectol mastercard, and route (eg virus 68 michigan purchase stromectol 12mg amex, oral vs nasal) can impression the quantity of drug absorbed and ought to be considered when utilizing pulmonary drug delivery units corresponding to nebulizers or inhalers. For medications that undergo intensive first-pass metabolism, bioavailability will increase as the blood supply bypasses the liver from the lower rectum on to the inferior vena cava. Availability of rectal dosage types varies and use of oral medications or different dosage varieties rectally is predicated on limited studies and case reviews. High osmolality and huge volume type may present as limitations to using an oral liquid formulation for rectal use. Volume of Distribution In pediatric sufferers, obvious volume of distribution (Vd) is normalized based on physique weight and expressed as L/kg. Extracellular fluid and total body water per kilogram of body weight are elevated in neonates and infants, leading to greater Vd for water-soluble medication, such as aminoglycosides, and decreases with age. Therefore, neonates and infants often require greater doses by weight (mg/kg) than older kids and adolescents to obtain the identical therapeutic serum concentrations. This displacement could end in a complication known as kernicterus, from bilirubin encephalopathy. Accordingly, the use of products containing ethanol or propylene glycol can lead to elevated toxicities, together with respiratory despair, hypoglycemia, hyperosmolarity, metabolic acidosis, and seizures, and thus must be averted in neonates and infants. Increased dose requirements by physique weight (eg, mg/kg) for some hepatically metabolized medicines (eg, phenytoin, valproic acid) in young youngsters (ie, ages 2�4 years of age) are theorized because of an elevated liver mass to physique mass ratio. Glucuronidation by the uridine diphosphate glucuronosyltransferases, in distinction, is immature in neonates and infants, reaching grownup values at 2 to four years of age. This accumulation can lead to "gasping syndrome," which incorporates respiratory depression, metabolic acidosis, hypotension, seizures or convulsions, and gasping respirations. The use of plasma creatinine focus for estimating glomerular filtration rate in infants, kids, and adolescents. Children with cystic fibrosis additionally present with higher renal clearance of drugs corresponding to aminoglycosides, compared with kids with out the illness, requiring greater doses by weight and more frequent dosing intervals. Blood samples, cerebral spinal fluid, and urine had been collected for Gram stain and culture, still pending results. Given his poor oral intake on admission, the group requests the consultation regarding antibiotic selection. Dilution of parenteral drugs may be necessary to measure smaller doses for neonates. However, a higher concentration of parenteral medications could also be essential for patients with fluid restrictions, such as premature infants and patients with cardiac anomalies and/or renal illness. Appropriate stability and diluent choice data ought to be obtained from the literature. Children younger than 6 years are sometimes not able to swallow oral tablets or capsules and may require oral liquid formulations. Not all oral drugs, especially these unapproved for use in infants and kids, have a commercially obtainable liquid dosage kind. Use of a liquid formulation compounded from a strong oral dosage form is an possibility when compounding and stability data can be found. Factors corresponding to drug stability, suspendability, dose uniformity, and palatability should be thought of when compounding a liquid formulation. Palatability of a liquid formulation may be enhanced by utilizing easy syrup or OraSweet. If no dietary contraindications or interactions exist, doses could be mixed with meals objects similar to pudding, fruit-flavored gelatin, chocolate syrup, applesauce, or other fruit puree instantly earlier than administration of particular person doses. Most hospitals caring for pediatric patients compound formulations of their inpatient pharmacy. Limited accessibility to compounded oral liquids in neighborhood pharmacies poses a greater challenge. A record of neighborhood pharmacies with compounding capabilities should be maintained and provided to the mother and father and caregivers earlier than discharge from the hospital. Off-label use of treatment is the use of a drug outside of its approved labeled indication. Common Errors in Pediatric Drug Therapy Prevention of errors in pediatric drug remedy begins with identification of possible sources. One of the most typical causes for medication errors on this specialized inhabitants is inaccurate Medication errors dosing such as calculation error. It is crucial to verify accurate weight, top, and age for dosing calculations and allotting of prescriptions because pediatric sufferers are a vulnerable inhabitants for treatment error. Consistent items of measurements in reporting affected person variables, such as weight (kg) and top (cm), should be used. Dosing units similar to mg/kg, mcg/kg, mEq/kg, mmol/kg, or units/kg should also be used precisely. Given the age-related variations in metabolism of components, corresponding to propylene glycol L O 2 Routes of Administration and Drug Formulations L O 4 Depending on age, illness, and disease severity, different routes of administration could additionally be thought of. It has also been famous that these medicines could also be much less efficient in children youthful than 6 years compared with older youngsters and adults. A parent/caregiver might inadvertently overdose a toddler on one lively ingredient, such as acetaminophen, by administering acetaminophen suspension for fever and an acetaminophencontaining mixture product for chilly symptoms. Signs or signs of Reye syndrome, usually showing several days after start of a viral infection, are relatively nonspecific, together with diarrhea, persistent vomiting, increased respiratory price, increasing lethargy, and seizure. Strength or concentration of drug must also be clearly communicated by the clinician in prescription orders. Similarly, labels that look alike might lead to drug therapy errors (eg, mistaking a vial of heparin for insulin). Dosing errors of combination drug merchandise may be prevented by utilizing the proper element for dose calculation (eg, dose of sulfamethoxazole/trimethoprim is calculated based on the trimethoprim component). Use of standardized concentrations and programmable infusion pumps, corresponding to smart pumps with built-in libraries, is encouraged to minimize errors with parenteral drugs, especially these for steady infusions corresponding to inotropes. For example, colic is a condition of unclear etiology during which an infant cries inconsolably for over a couple of hours in a 24-hour period, usually throughout the same time of day. Symptoms of extreme crying normally enhance by the third month of life and often resolve by 9 months of age. Some dad and mom are advised by household and friends to use different treatments, such as gripe water, to deal with colic. For instance, treatment of the common cold in youngsters is much like adults, including symptom management with enough fluid consumption, rest, use of saline nasal spray, and acetaminophen (10�15 mg/kg/dose each 6�8 hours) or ibuprofen (4�10 mg/kg/dose each eight hours) for relief of discomfort and fever. Other products, such as a topical vapor rub or oral honey, have Medication Administration to Pediatric Patients and Caregiver Education Considering the challenges in cooperation from infants and younger kids, medicine administration can turn into a difficult task for any parent or caregiver. One widespread issue to contemplate is ease of measurement and administration when selecting and dosing pediatric drug remedy. Clinicians should examine concentrations of available products and round doses to a measurable amount. For example, if a affected person had been to obtain an oral formulation, corresponding to amoxicillin four hundred mg/5 mL suspension, and the dose was calculated to be 4. Rounding the dose by 10% to the closest easily measurable quantity is often practiced for many medicines (eg, antibiotics); however, medicine with slim therapeutic indices (eg, anticoagulants) are exceptions to this guideline.

12mg stromectol with amex

The product produced underneath unsanitary situations triggered more than 60 deaths and 750 instances of an infection across the United States (5) best antibiotics for sinus infection mayo clinic generic stromectol 6mg without a prescription. Manufacturers of sterile products must due to this fact remain compliant with all laws and requirements pertaining to the manufacture of sterile merchandise including adherence to good manufacturing practices in the country or area where they want to antibiotic 1 hour prior to incision generic 6mg stromectol amex manufacture or market their products antibiotic resistance mechanisms in bacteria buy cheap stromectol 6 mg online. Terminal Sterilization Terminal sterilization normally entails filling and sealing product containers beneath high-quality environmental situations. Products are filled and sealed in this sort of environment to minimize the microbial and particulate content material of the in-process product and to help make certain that the next sterilization course of is successful. The product in its last container is then subjected to a sterilization process corresponding to heat or irradiation. Generally, terminal sterilization has fewer variables when compared with aseptic processes. Aseptic Processing Aseptic processing entails the interplay between numerous completely different processes, all of which must be designed, executed, and controlled to be able to yield sterile merchandise. In an aseptic process, the drug product, container, and closure are first subjected to sterilization methods individually, as appropriate, and then brought collectively. Before aseptic meeting into a final product, the individual parts of the ultimate product are usually subjected to varied sterilization processes. For instance, glass containers are subjected to dry warmth, rubber closures are subjected to moist heat, and liquid dosage forms are subjected to filtration. An error in any process could potentially result in the distribution of a contaminated product. Therefore, every individual process in an aseptic course of requires validation and control. Any manual or mechanical manipulation of the sterilized drug, parts, containers, or closures prior to or throughout aseptic assembly poses the danger of contamination and thus necessitates cautious control. A terminally sterilized drug product, however, undergoes final sterilization in a sealed container, thus limiting the potential of error. The necessities mandate that parenteral and ophthalmic preparations which are marketed in the United States must be sterile (6). The guidelines include each small-molecule products and biologics, together with these derived from biotechnology and vaccines. However, science and risk-based approaches ought to be thought of when choosing the manufacturing process. An instance is when the active within the product is inherently unstable to the circumstances of terminal sterilization. In such circumstances, it could be prudent to choose aseptic processing strategies to manufacture the sterile product. Regulatory and Technical Framework While regulatory expectations are broadly aligned in phrases of the general necessities regarding sterility of pharmaceutical products, some variations do exist within the specific concerns and necessities throughout the totally different well being authorities. These differences arise primarily based on native laws, rules, directives, pharmacopoeial necessities, specific guidance documents referring to manufacture, and testing of sterile preparations. Regulatory authorities have undertaken newer initiatives and developed regulations both to improve the quality and security of sterile drug products in response to specific incidents or to incorporate scientific and technological developments. Two noteworthy examples of the companies creating guidelines in response to particular events are the following: � During the period between 1980 and 2000, the most important cause for sterile drugs recalled in the United States was due to non-sterility or lack of sterility assurance (1). Additionally, viral inactivation/removal and that of other impurities of organic origin should be demonstrated to guarantee the protection of biotechnologically derived products. When validation of an aseptic course of presents particular issues due to the smaller batch sizes for investigational medicinal merchandise, the rule recommends performing validation at a larger scale-up to the full production scale. Ancillary pointers and pharmacopoeia sections that had been used as a reference in writing this chapter are summarized in Table forty nine. However, some variations do exist in each the extent of detail and the distribution of subjects across the guidelines. It is necessary to note that the authorized and/or enforcement status of those documents may be different in every area or nation and depends on the applicable local rules and legal guidelines. Therefore, each doc and the necessities in it carries a different legal or enforcement standing. While there are heaps of similarities in regulatory expectations, important variations had been additionally famous in the regulatory requirements between the guidelines. These variations might generally current some distinctive challenges in regulatory interpretation and implementation at the manufacturing site stage, for instance, throughout review of promoting purposes, variations, and supplements, or throughout well being authority inspections of sterile manufacturing sites. In the floor diagram, and/or in an accompanying narrative, the next data must be offered: (i) product, personnel, equipment, waste, and airflow; (ii) illustration or indication of which areas are served by every air-handling unit; and (iii) air pressure differentials between adjoining areas. Buildings and Facilities Regulatory agency expectations differ with respect to the facilityrelated info submitted in advertising purposes. The sections under provide data on regulatory expectations concerning sterile manufacturing areas. The typically beneficial air change rate is 30 times per hour in the direct support space and 20 occasions per hour in Grade C workrooms among oblique help areas. Clean Room Classification Clean room classification that offers with the ability of the facility to keep acceptable particulate control and routine monitoring is integral to the qualification of cleanrooms. All tips require initial classification to be accomplished in both the "at relaxation" and the "in operation" state. The "Environmental Monitoring" part contains details on environmental monitoring. The guideline recommends as essential to implement further supplementary measures to stop or decrease the danger of contamination during crimping by microbial or nonviable particles. Air Changes and Cleanup Time Air change price is an important cleanroom design parameter and is usually decided by the number air modifications per hour primarily based on the category of the room, variety of personnel working in the space, and frequency of access the room. Such situations are usually supplied by laminar airflow techniques which ought to present a homogeneous air pace within the vary of zero. Maintenance of laminarity together with uniformity and effectiveness must be demonstrated and validated. Background setting for Grade A important area Types of Operations (Examples) � Sterilization activities. Grade B Grade C and D Clean areas for carrying out less crucial levels within the manufacture of sterile products. Weighing and preparation processes should preferably be conducted in Grade C or cleaner areas. Regulatory Considerations 1071 properties, right into a previously sterilized container. Health authorities typically advocate the use of redundant sterilizing filters when acceptable, to present additional assurance of sterility of the ultimate product. Filters for sterile liquid filtration ought to be chosen based mostly on their physicochemical properties, biological security profile, bacterial retention efficiency, extractable profile, compatibility with pharmaceutical merchandise, and course of characteristics such as required membrane floor areas in accordance with the evaluation protocol or process (1).

References

- Bakaeen FG, Reardon MJ, Coselli JS, Miller CC, Howell JF, Lawrie GM, Espada R, Ramchandani MK, Noon GP, Weilbaecher DG, DeBakey ME. Surgical outcome in 85 patients with primary cardiac tumors. Am J Surg 2003;186:641-647; discussion 647.

- Lamhonwah AM, Gravel RA. Propionic-acidemia: absence of alpha chain mRNA in fibroblasts from patients of the pccA complementation group. Am J Hum Genet 1987;41:1124.

- Chatkupt S, Lucek PR, Koenigsberger MR, et al: Parental sex effect in spina bifida: a role for genomic imprinting?, Am J Med Genet 44(4):508n512, 1992.

- Finn AV, Joner M, Nakazawa G, et al. Pathological correlates of late drug-eluting stent thrombosis: strut coverage as a marker of endothelialization. Circulation. 2007;115:2435-2441.